Operational Excellence, Performance Management and Continuous Improvement

Which are your goals? How do you plan to reach them? How are you going to engage all employees in the process? And what do you and your colleagues need in order to contribute to the process?

Operational Excellence and Performance Management enhance each other: Operational Excellence enables robust processes while Performance Management ensures further improvements and the leadership to sustain the gains. The result: empowered employees taking ownership and contributing individually and as a team to the goals of the organization.

Engaging all employees helps to get the best result. It is an important part of Policy Alignment and Policy Deployment.

Performance Management

When you are in an early stage of the process we suggest to take the following steps:

Steps in Performance Management implementation:

- Policy Alignment: Which goals do we have? What do we want to achieve? And why do these items get priority? Where do we want to be in 3-5 years from now, what is the direction? And how are we going to measure and to celebrate success?

- Policy Deployment: What do the goals mean for the respective department and teams? What and how can they contribute? How are we going to organize it? What can we contribute to these goals in the next 3-5 years?

- Introduction of a Daily/Weekly/Monthly Management System: how are things going? Have we improved compared to yesterday? Which issues are a hindrance? Which things can we resolve ourselves, and where do we need help from others? And has the issue been addressed at the right level?

- Frequent evaluation of the progress. Adjust where and when needed. Determine the training and coaching needs. Celebrate Success! Include improvements that need more time or resources to implement in a Focused Improvement project as part of your Operational Excellence Program.

Operational Excellence

There are three partially overlapping methods/ programs:

1. TPM: Total Productive Maintenance

2. Lean Management

3. Six Sigma

1. TPM, Total Productive Maintenance

TPM is a program for improving operational performance. The original Japanese characters mean "Total People Participation".

The program consists of building blocks, the "TPM pillars" that address specific items. The following TPM pillars are relevant in any program:

- Safety

- Loss Analysis and Policy Alignment and Deployment

- 5 S method for workplace organization and standardization

- Training and Education

- Autonomous Maintenance, Operator Driven Maintenance

- Planned Maintenance

- Focused Improvement

Pillars that are usually started later:

- Early Equipment Management

- Office TPM

- Quality Maintenance

2. Lean Management / Manufacturing

This program gets a lot of attention, with the image that Lean is about cost cutting. The lean meaning is to create (more) value for your customer. This can often be achieved by eliminating the lean 7 wastes from the process. Eliminating the wastes is an important success factor since it enables serving your customers in a better way.

The explanation below primarily focusses on 'assembly' production. The philosophy is much wider applicable, including service organizations and administrative departments!

The road towards Just in Time production

1. Awareness, knowing what can be achieved with JIT

2. Value stream mapping and 5S workplace organization and standardization

3. Line integration

4. One piece flow

5. Pull system, KANBAN ('pull' instead of 'push')

6. Line balancing

7. Standardization

1. What you can achieve with Lean Production?

The following benchmark figures are available:

Reduction of Work in Progress (WIP) with 70 %

Reduction of throughput time (lead time) with 90 %

Reduction of floor space with 75 %

Additionally, Lean results into significantly improved delivery performance and an improved quality.

2. VSM Value Stream Mapping and the 5 S method for workplace organization and standardization)

Value stream mapping is a way to map your material and information flow, which facilitates to determine improvement opportunities.

The 5S program ensures an engaged workforce creating a well-organized, efficient and safe workplace.

3. Line integration

This step realizes the flow concept, which is very important to spot problems instantly. It also eliminates or reduces intermediate stock.

4. One piece flow

A crucial step to reach your goal: produce on customer demand, the right quantity at the right moment at minimal cost. This also means that change over times are attacked and eliminated. Once this is realized, batch size does not matter anymore, since it does not reduce production efficiency, and therefore a small quantity does not mean extra cost. This already has been achieved in car manufacturing, where batch size now is equal to "one"!

5. Pull system (KANBAN)

The next important step: products are not pushed into production anymore (hoping some day they will come out at the other end), but 'pulled' the moment the customer asks for it. This results in a shorter lead time and lower cost.

6. Line balancing

The TAKT time (or: 'pulse rate' or 'heartbeat') from the production steps are now balanced.

7. Standardization

To hold the gains, and to continue on the continuous improvement path.

Lean Meaning

Lean Production means to apply this concept, in order to meet your customers demand efficiently and cost effectively. Very often the Lean 7 Wastes are mentioned. The Lean Meaning however is to create value for the customer, removing non value adding activities is one of the ways to do this.

Kaizen

KAIZEN means 'continuous improvement', in this context most often referred to as 'KAIZEN blitz': a short, intensive in house workshop to realize these principles and to demonstrate their power. The Kaizen method is an important success factor in continuous improvement.

3. Lean 6 Sigma

Six Sigma focusses on elimination of variation by determining the root cause for this variation, and then to eliminate these causes. Very often this is also called Statistical Engineering. Design of Experiments, Measurement System Evaluation and Statistical Process Control (SPC) are all part of it.

The Design of Experiments method has the following steps:

1. Determine if the method can solve the specific issue

2. 'To translate' the issue (the characteristic) to a measurable quantity

3. To reduce the search area ('Intelligent Searching')

4. To determine the cause(s)

5. To quantify the effect of the causes

6. To verify the suggested improvement

7. To determine process parameter borders

8. To control the process

Techniques in TPM Total Productive Maintenance, Lean Management and 6 Sigma

We shall further elaborate on the following techniques:

1. Value Stream Mapping

2. 5S workplace organization and standardization

3. SMED, Single Minute Exchange of Dies, Setup Time Reduction

4. OEE, Overall Equipment Effectiveness

5. Measurement System Evaluation or Gauge Analysis

1. VSM Value Stream Mapping

Lean Management / Manufacturing helps to improve your processes. VSM Value Stream Mapping or Value Stream Analysis is an important instrument, since it maps your process in several categories. The key point of view in Value Stream Mapping is the lead time: all process steps are analyzed in terms of actual versus theoretical minimum lead time. A multi-disciplinary team maps the material and information flow as well as disturbances and improvement ideas. With the "current state" as starting point a "future state" is developed. The improvement ideas are evaluated and implemented.

Very often these improvement ideas are easy to implement, at a low cost or no cost basis. The benefits are usually substantial: less stock, minder handling, better quality, less rejects and an improved safety.

2. 5S workplace organization and standardization

The 5 S method for workplace organization and standardization is a structured program to organize the workplace. It enhances teamwork, ownership and (self)discipline from all employees. The 5 S process strengthens safety, process improvements, a more efficient way of working, improving product quality and the felling of controlling the workplace.

The 5S program consists of 5 activities all starting with an "S":

Sorting deals with the contents of a workplace, and removes all items that are not needed there.

Setting in Order refers to "a place for everything, and everything in its place" to enable easy access to needed items.

Shining refers not just to cleaning, but to "being proud" about the way the workplace is organized.

Standardizing refers to having standards that everyone has to adhere to. Visual management is an important aspect to facilitate easy understanding of these standards.

Sustaining refers to training of all employees and communication to all employees to ensure 5S application.

The 5S management program facilitates an excellent performance:

Safety: a well organized and orderly workplace is a safer workplace. 5S activities remove clutter, visual indicators alarm people for hazardous situations.

Improving production efficiency: 5S supports a smooth production process in various ways. Searching for tools is eliminated, flow principles are applied, tools storage is done where they are needed most. Location indicators visualize how things have been organized, and non conformities are seen at once.

Quality improvement: Daily activities like inspection help to keep the production process in the right condition. Defects are prevented, because deviations are spotted before they result into defects.

|

3. Changeover time reduction: SMED Single Minute Exchange of Dies

"Reduce changeover times from hours to minutes"

The rapidly increasing diversity and smaller batch sizes cause setup time reduction to be of crucial importance for the profitability of many companies. For example, bottling industries sometimes spend more than 20% of their planned production time on changeovers. Fortunately, these setup and changeover times can be reduced significantly when the SMED system is applied. The SMED system has a proven track record in many types of industries.

Single Minute Exchange of Dies (SMED) is the approach to reduce output and quality losses due to changeovers. The method has been developed in Japan by Shigeo Shingo, and has proven its effectiveness in many companies by reducing changeover times from hours to minutes. Analyzing the changeover process, combined with a stronger sense of teamwork and ownership lead to significant reductions in setup and changeover times.

The SMED process consists of the following 4 phases:

1. Mixed phase

2. Separated phase

3. Transferred phase

4. Improved phase with often an improvement of more than 50%!

The method's strength is the systematic approach to analyze what is actually done and how time is spent during the changeover activity. Through the analysis, a better understanding is gained on how to do certain activities, when the line is running. Also it is determined, what can be done to reduce the "fine tuning" activities after the actual changeover.

Changeover loss is one of the 6 big losses that have been defined within the TPM method.

More information: Shigeo Shingo: "A revolution in manufacturing, the SMED system".

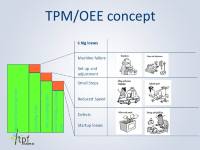

4. OEE, Overall Equipment Effectiveness

The OEE index has been developed by the JIPM (Japan Institute for Plant Maintenance). It is one of the pillars within the TPM method. The method distinguishes 6 loss types, and 3 categories: availability, speed losses and quality rate. The method\'s strength is that it makes the losses more transparent, and from experience we know that a good analysis provides a very good "picture" of the actual situation, which helps to determine both short and longer term improvement activities, including quantified benefits from each of the improvements. When you do not measure it yet, it is very likely your OEE is below 50%!

Gross Available hours

Gross Available hours (#days/year: 365, 24 hours/day, 7 days/week)

Planned Downtime

For example: vacation, holidays, not 168 hours/week, not enough load.

1. Breakdowns/Machine failures

Downtime because of machine failures

2. Setup and adjustment

For example between product types, including "warmup time" after the actual changeover. Changeover time should be included here, and should not be included in the planned downtime. Changeover time can be reduced by applying the SMED system.

3. Small stops

When these have not been causes by logistics. Small stops are typically shorter than 5-10 minutes. Small stops are typically minor adjustments, for example cleaning etc. This is different from machine failures, where you will usually need maintenance personnel to solve it.

4. Speed losses

Speed losses are caused when a machine runs more slowly than its optimal/maximum speed.

5. Rejects during production

This includes all rejects and repairs during normal production, so after running in/warmup phenomena.

6. Rejects during running in/ warmup

This includes all rejects and repair during startup/running in/ warmup.

Nowadays there are software solutions to monitor and analyze the OEE, like Patch OEE.

Patch visualizes the status of all machines and enables a quick analysis on causes for OEE losses.

5. Measurement System Evaluation or Gauge Analysis

Does your measurement system qualify for the purpose? Do you have unjustified rejects or -maybe even worse- unjustified approved and shipped products? How much variation is caused by your measurement system? Have you ever done a measurement system evaluation next to the calibration?

Measurement Systems come in different size and shapes: from relatively simple to very extensive/complicated. In the semiconductor and electronics industry sometimes measurement systems are specifically developed for one product or product group. During the development of these systems certain product defects are anticipated and these systems are designed to detect those defects.

A new situation arises when the measurement system is put into practice (or a new product is launched): only then it becomes clear which defects have a more systematic presence and which defects are random. It then also becomes clear whether the defect level allows for sample based testing which is less costly.

Practice shows us:

- The measurement system is more than the machine. Several times we have seen that the influence of the environment was bigger than suspected. The results: unjustified rejects and rework with lots of efforts and stress to deal with it.

- The production process (assembly) and measurement program must be well aligned. Sometimes only few measurements are sufficient as feedback to the assembly line. When there are multiple measurement points across the production chain, your measurement strategy across the chain can lead to significant savings.

- A systematic analysis requires a careful preparation and is quite time consuming, apart from the expertise required. Sometimes there are not sufficient resources available to analyze the effectiveness of the measurement system since are tied up in solving ad hoc issues.

Sometimes measurement systems can be used more effectively:

More effectively also means that more products can be tested (measured) without any disadvantage for product quality or slip through. This is particularly valuable when the choice has to be made: do we invest in (often expensive) extra measurement equipment + the necessary staff + training + maintenance, or extend capacity leading to extra cost.

A systematic effectiveness analysis from the measurement system -which is more extensive than a standard measurement system evaluation or gauge analysis- helps to acquire a balanced view on the effect of reducing or eliminating specific measurement steps (tests), including the final product test. It also helps to identify which variables are the most critical ones. This systematic analysis has led to some remarkable results in terms of savings (no additional equipment needed), as well as in terms of opportunities (reduction of intermediate and final testing). It also showed what was needed to sustain the gains.